DEC.SDS™

solvents, inks and resins | storage tanks and distribution systems

Solvents, inks, and resins are all flammable and hazardous materials that require proper storage and handling. Storage tanks and distribution systems for these materials must be designed and constructed to meet specific safety standards.

Tanks are manufactured following several relevant standards, such as European EN-12285 (Workshop fabricated steel tanks for the aboveground storage of flammable and non-flammable water polluting liquids), DVS (German Welding Institute) 2205, and ASME (American Society of Mechanical Engineers), which give advice on wall thickness, quality control procedures, testing procedures, accreditation, fabrication and design criteria of final product.

The design and construction of solvents, inks, and resins storage tanks and distribution systems is a complex process that requires the expertise of qualified engineers and designers.

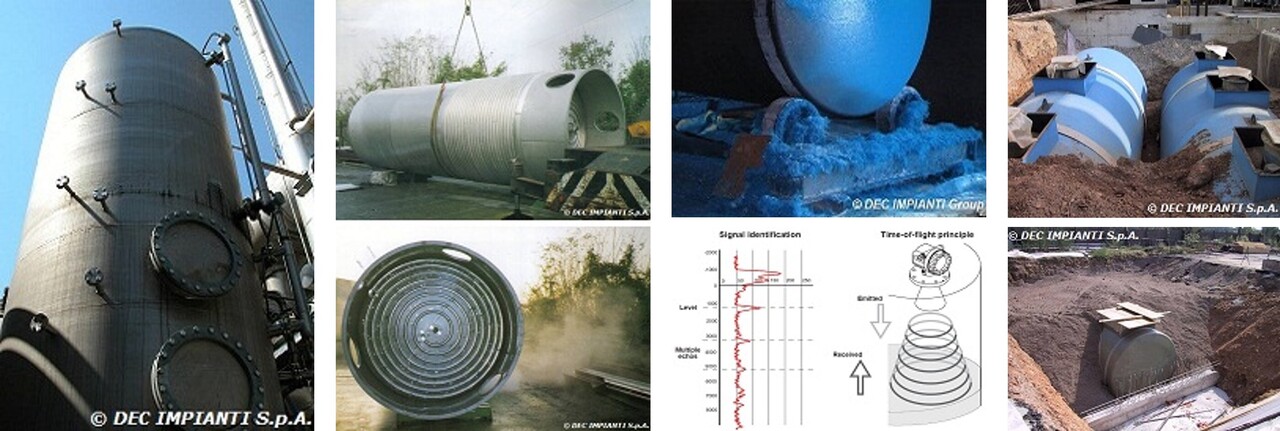

DEC.AST™ • above ground storage tanks

Above-ground storage tanks (ASTs) are typically made of steel (AISI-304 or ASI-316) and are mounted on above-ground structures. ASTs may be also often double-walled and equipped with monitoring systems.

DEC.UST™ • underground storage tanks

Underground storage tanks (USTs) are typically made of steel (carbon steel or stainless AISI-304 or ASI-316) and are buried below ground: USTs are often double-walled to prevent leaks, and they are equipped with monitoring systems to detect leaks and spills. The external wall is typically jacketed with filament windings like glass fiber/aramid or carbon fiber or with a bituminous compound, mainly for corrosion protection (cathodic protection).

DEC.TBS™ • tank blanketing system

A tank blanketing system with nitrogen is a safety system that uses an inert gas, such as Nitrogen (N2), to fill the empty space above a liquid in a storage tank. This helps to prevent oxidation, combustion, and other hazardous reactions.

Nitrogen (N2) is an inert gas, which means that it does not react chemically with other substances: this makes it ideal for use in tank blanketing systems, as it does not pose a risk of fire or explosion.

DEC.LDS™ • leakage detection system

DEC.LDS™ uses sensor(s) to actively detect vapors (LEL monitoring) that are created by leaks in the solvent storage area(s).

DEC.SGD™ • static ground detection

Static electricity can cause a number of problems, including fires, explosions, and equipment damage: by detecting static electricity, DEC.SGD™ will help to prevent fires, explosions, and equipment damage.

DEC.SGD™ is a device that continuously monitors the electrical potential between two points: if the electrical potential rises above a certain level, the static ground monitor will automatically inhibit any manual transfer operation.

DEC.WSN™ • water sprinkler nozzles

Water sprinkler/spraying nozzles can be used to protect AST tanks containing flammable solvents: the sprinklers should be placed around the tank in a way that will provide complete coverage, to cool it down in case a fire could impact the solvent tank. The sprinklers should be activated by a fusible link or other sensor that will detect a fire.

distribution systems

In addition to storage tanks, solvents, inks, and resins also require specialized distribution systems: these systems must be designed to prevent leaks and spills, and they must be able to pump and safely transport the materials from the storage tanks to the point of use.